We solve problems before they’re problems.

Almost all machine components give some type of warning prior to failure. Our state-ofthe-art Qualitest® diagnostic procedures identify these warnings and anticipate problems before they happen. Because we prevent expensive slow-downs and stoppages, our maintenance program may actually save you money.

Call us for an estimate of cost/savings to keep all your equipment up and running.

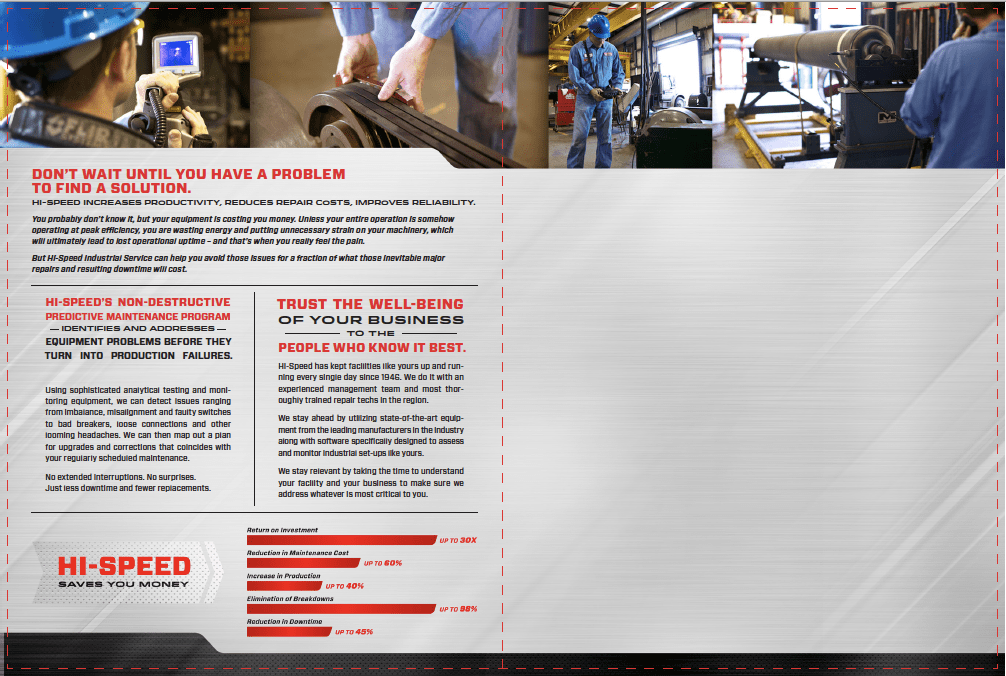

Predictive Maintenance Services

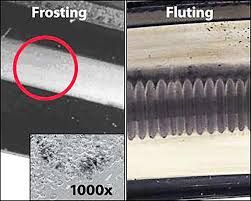

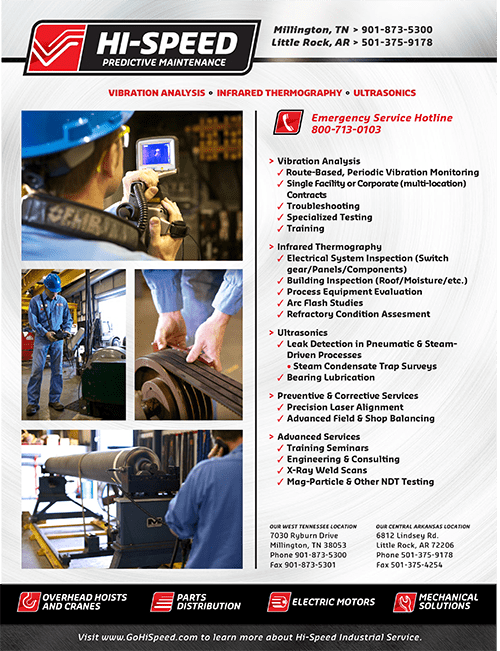

Vibration Analysis

- Route-Based, Periodic Vibration Monitoring

- Single Facility or Multi-location Contracts

- Troubleshooting

- Specialized Testing

- Training

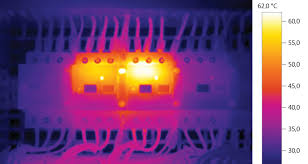

Infrared Thermography

- Electrical System Inspection (Switch gear/Panels/Components)

- Building Inspection (Roof/Moisture/etc.) Process Equipment Evaluation

- Arc Flash Studies

- Refractory Condition Assessment

iAlert Monitoring

Ultrasonics

- Leak Detection in Pneumatic & Steam- Driven Processes

- Steam Condensate Trap Surveys

- Bearing Lubrication > Preventive & Corrective Services

- Precision Laser Alignment

- Advanced Field & Shop Balancing

Advanced Services

- Training Seminars

- Engineering & Consulting

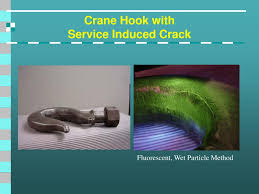

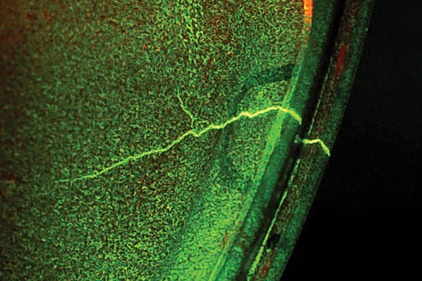

- X-Ray Weld Scans

- Mag-Particle & Other NDT Testing

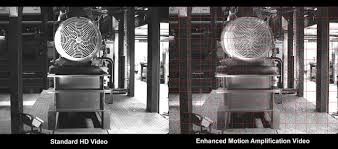

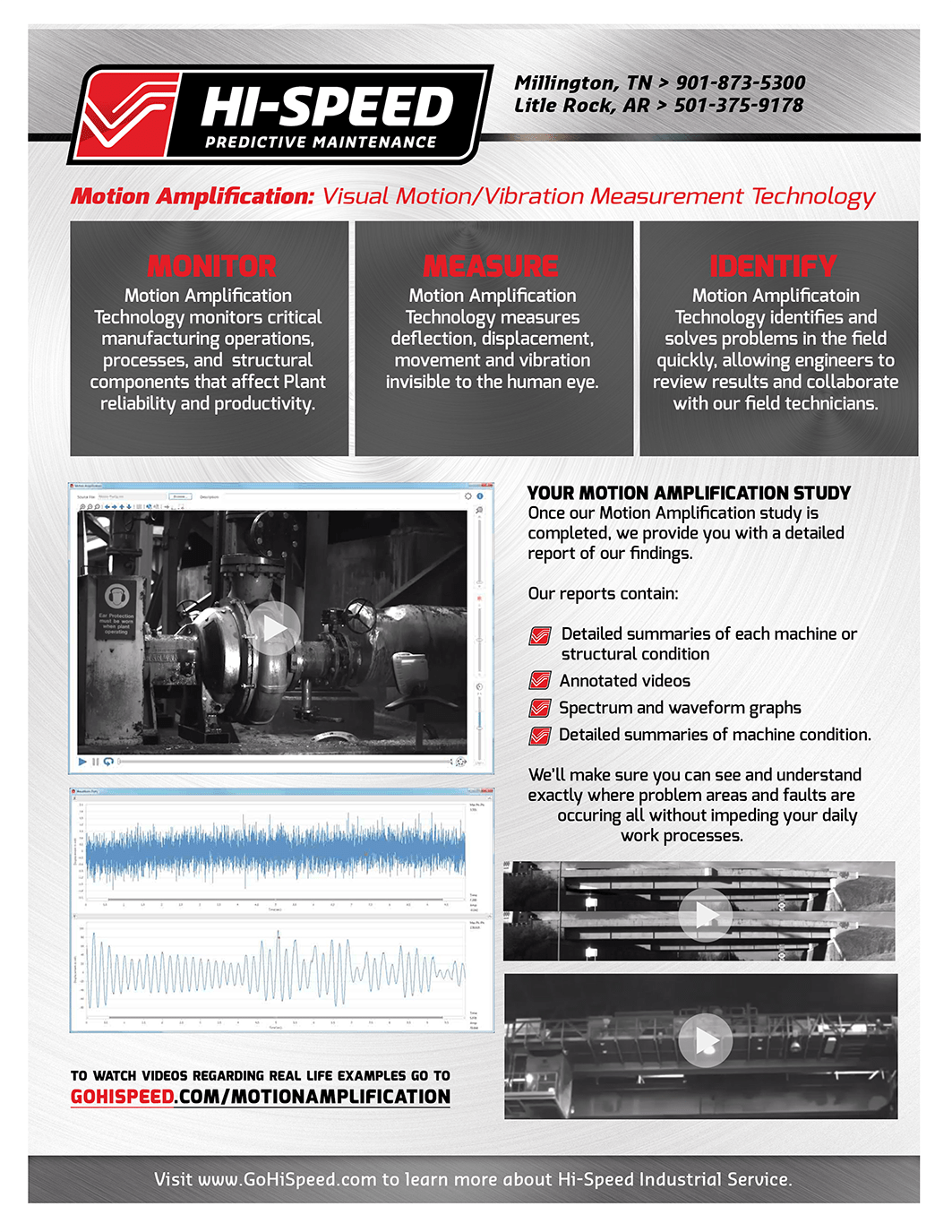

Motion Amplification

Photo Gallery

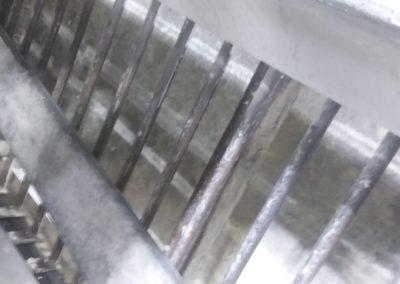

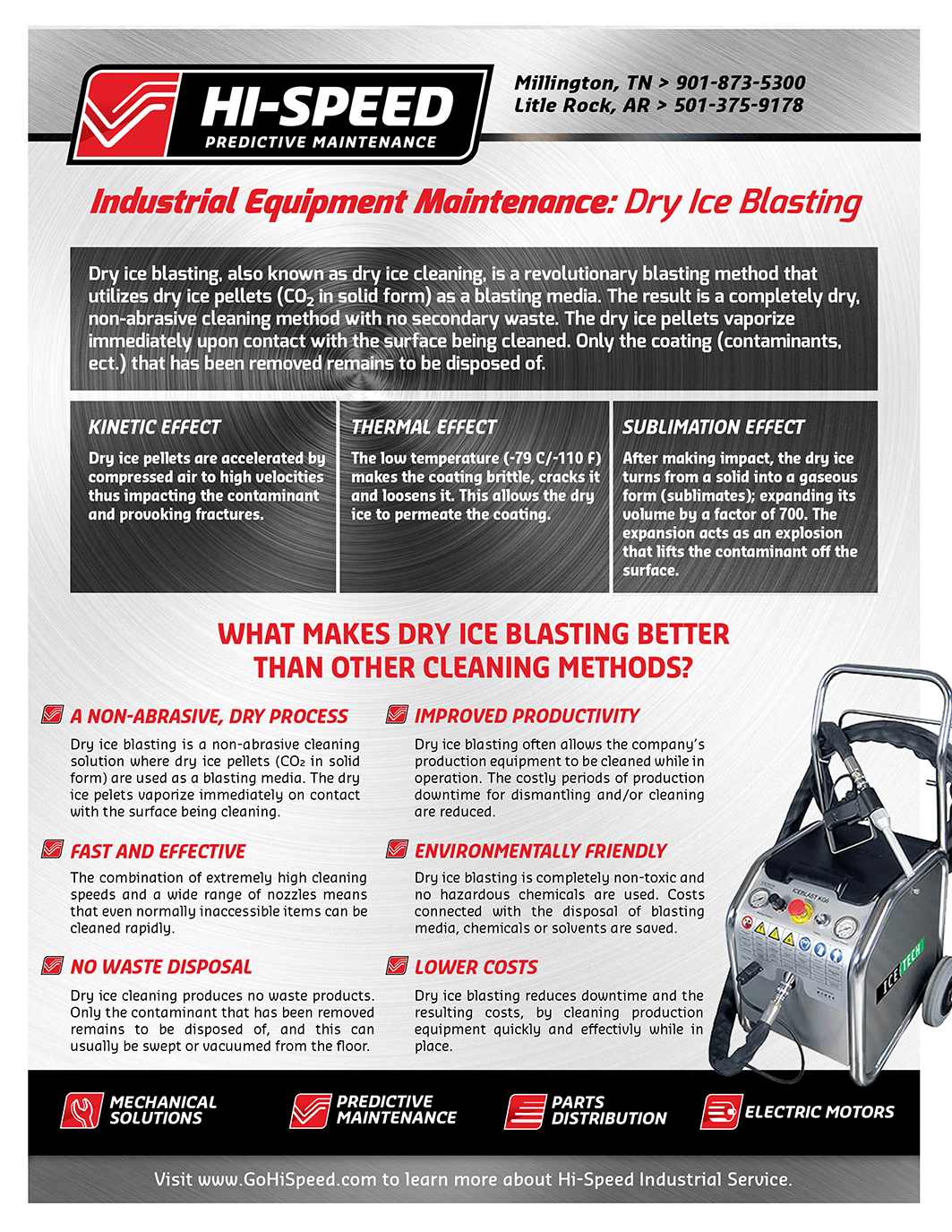

Dry Ice Blasting

Dry ice blasting, also known as dry ice cleaning, is a revolutionary blasting method that utilizes dry ice pellets (CO2 in solid form) as a blasting media. The result is a completely dry, non-abrasive cleaning method with no secondary waste. The dry ice pellets vaporize immediately upon contact with the surface being cleaned. Only the coating (contaminants, etc.) that has been removed remains to be disposed of.

Applications

- Electrical Equipment & Power Plants

- Electric Motors

- Generators

- Turbines

- Small Components

- Insulators & Switches

- Cable Ways & Trays

- Interior Auto Parts and Panel Molds

- Seat Molds

- Tire and Gasket Molds

- Glue Applicators

- Lubricating Systems

- Conveying Systems

- Cooling Fans

- Baking & Food Processing Equipment

- And Much Much More

PdMA Motor Testing Service

Combining the latest technology, analysis, and information systems, the PdMA MCEMAX is a complete motor / asset management for today’s motor management needs.

Benefits:

- Reduction in unexpected motor failures

- Less downtime, less scrap materials, better inventory controls

- Improved quality assurance

- Energy Cost Analysis

OUR VENDORS